Deformation by passion

Since 1975 we design and manufacture moulds and equipment for the cold deformation of metals

Experience

certified

Highly specialized young

team

Custom

Design

Products with a high technological content

Ask for advice for your project

We have been a family business on the cold forming market since 1975.

The attachment to the territory of origin, the passionate dedication to our work and the assiduous collaboration of highly qualified personnel, have allowed us to achieve a high specialization and an important recognition in the international arena.

The company has invested continuously since 2007, in correspondence of the first crisis of the sector, to date:

– the new, wider and more efficient Presezzo site, also from an environmental and energy point of view;

– the long path of consulting to achieve important certifications (9001, 14001, 18001 and TS 16949) that have led to a qualification of the activities of Ma-El, encouraging the penetration in new markets and expanding the product range;

– the new ERP system, developed in collaboration with a young group of computer scientists, eager to experiment and experiment in this new challenge.

Foundation of the company by Elvino Mazzoleni.

worldwide expansion

Relocation

Certification acquisition 2001:2015

Transfer to the current location in Presezzo with factory in an area of 5500 m2 with strategic location

Acquisition of IATF and ISO 14001 certifications

Creation Ma-El Itd Yantai for Asian market development

generational shift

New extension of the headquarters that now has 10,000 square meters of surface

Further development of Asian Yantai site with 3500 square meters of surface area and advanced machinery

Turnover 10 million € and 50 employees

countries served

Millions of pieces produced annually

Continents reached

services

Analisi Feasibility

Co-design and analysis Fmea

Study and consulting of customized solutions

From simple mould to complete plant

Production optimization of costs

Geometry analysis and raw material consumption

Series production of stamped parts

Focus on small items and high volumes

Equipment for the deformation of metals

From progressive moulds to transfer equipment

integrated processes

Unique partner for your solutions

what we do

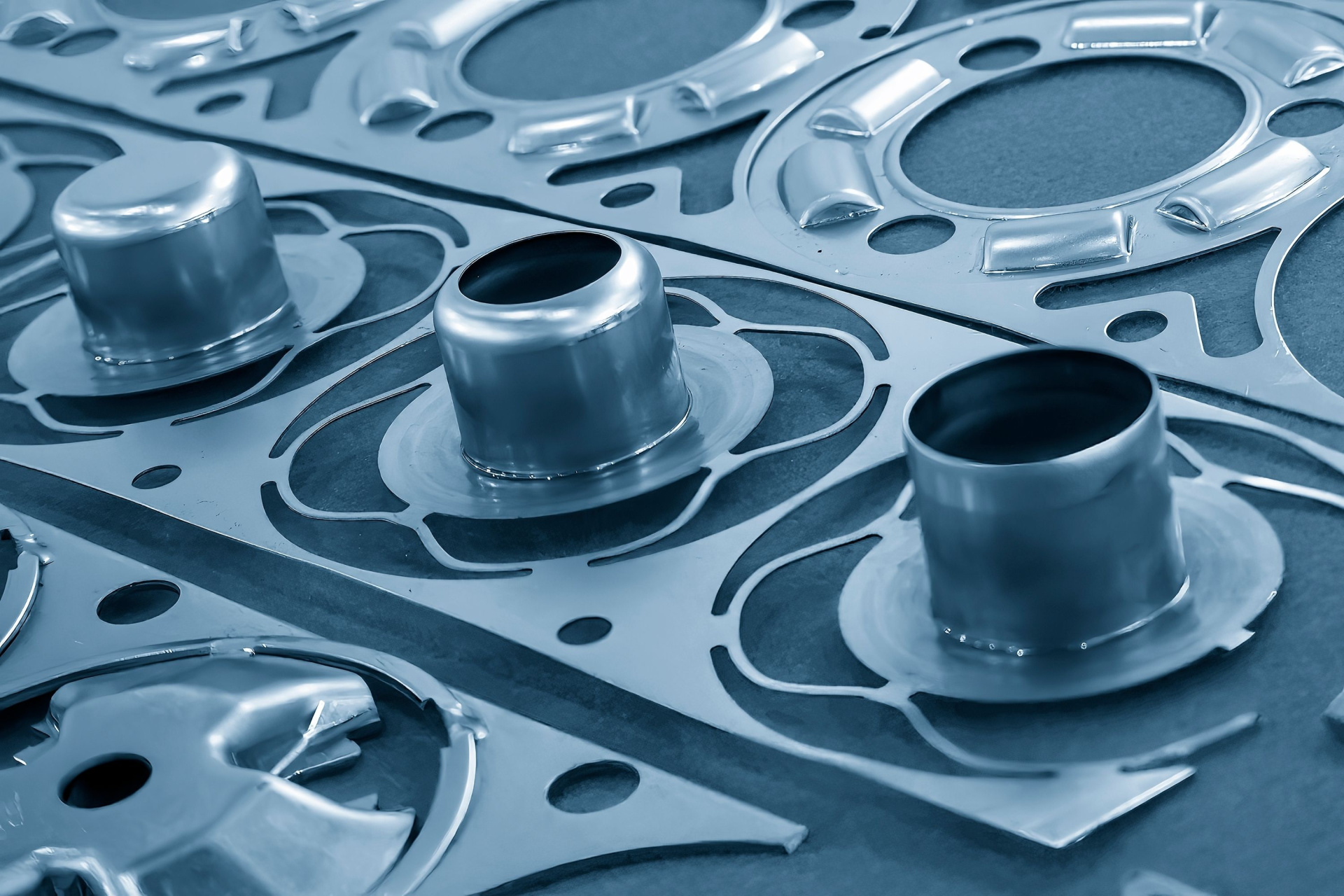

We design and manufacture moulds and equipment for the cold deformation of metals assisting the customer along the entire production process from the design, to the realization until the final testing of the mould and we produce directly for the customer deep-drawn components with high added value.

In summary our work consisting in:

transfer dies

Progressive moulds

Moulds for fine blanking

Special production of fine blanking

Special production with high technological content

Ask for advice:

035 451 7251

sectors

Automotive

Medical

HVAC

Appliance

How we do

Each of our products has a soul because it has been designed, designed and manufactured with passion, dedication and professionalism, using the best possible technologies and where necessary relying on industry leaders of high value.

Suppliers

Quality

Fleet Machinery and equipment

Sustainability

Information Technology

certification

Ask for advice:

035 451 7251

News

REPOWER energy certification: we are a green structure inside!

Ma-El has obtained the important Renewable-Energy Certificate of Origin from REPOWER: we are a green structure inside! The certification of energy origin for a company is a document that certifies the origin and type of energy used in business operations. This...

Green Factory – Life, for cleaner air in the factory

LIFE Green Factory project: providing an integrated system of environmental sanitization that, through a series of air quality detectors distributed throughout the plant, is able to constantly monitor the pollution parameters of the entire production siteo. This is,...

MAEL new investment in sustainability

In order to contribute even more to our commitment to sustainability, when the company expanded in 2021, we installed in the new building other solar panels and a new plant with photovoltaic panels, already present instead in the original shed. Solar energy is a...