what we do

We design and manufacture moulds and equipment for the cold deformation of metals assisting the customer along the entire production process from the design, to the realization until the final testing of the mould and we produce directly for the customer deep-drawn components with high added value.

In summary our work consisting in:

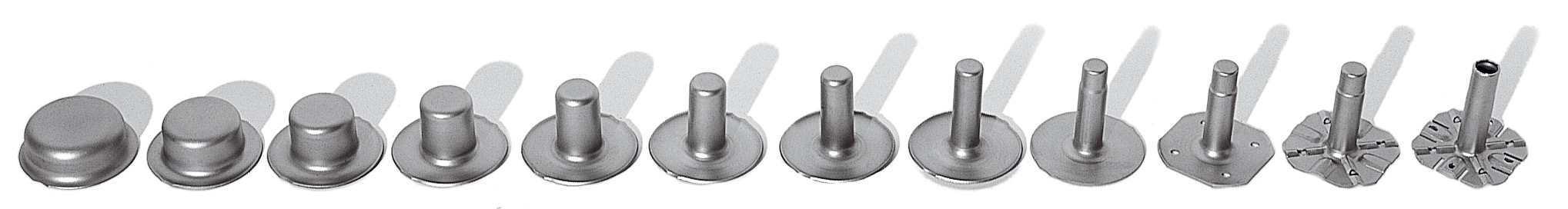

transfer dies

Progressive moulds

Moulds for fine blanking

Special production of fine blanking

Special production with high technological content

Ask for advice:

035 451 7251

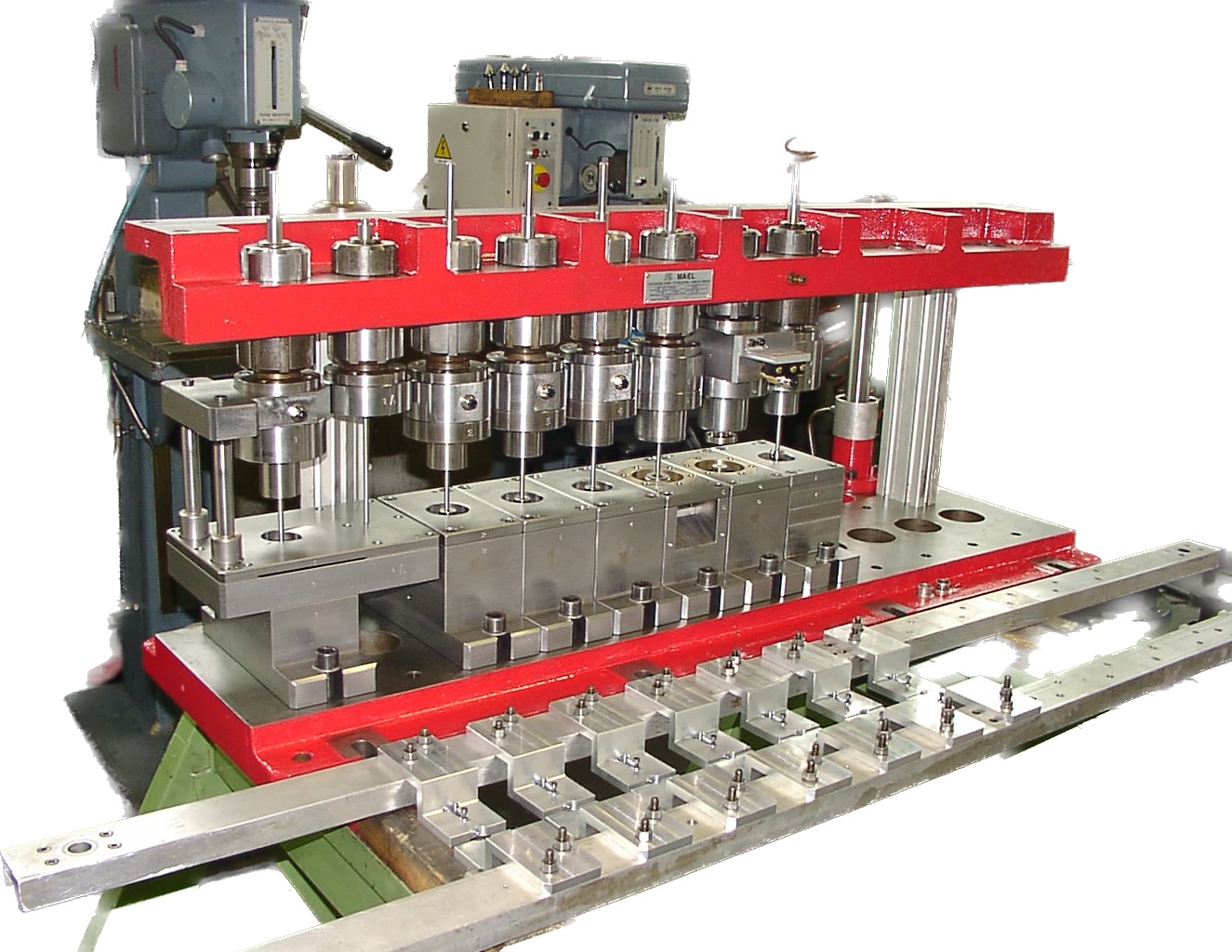

transfer dies

Specific for drawing or where it is necessary to have additional operations.

Raw material optimization and maximum waste reduction.

Possibility of off-axis operations with complete embossing of all profiles.

Complex operations within the same production cycle.

Integrated dimensional checks

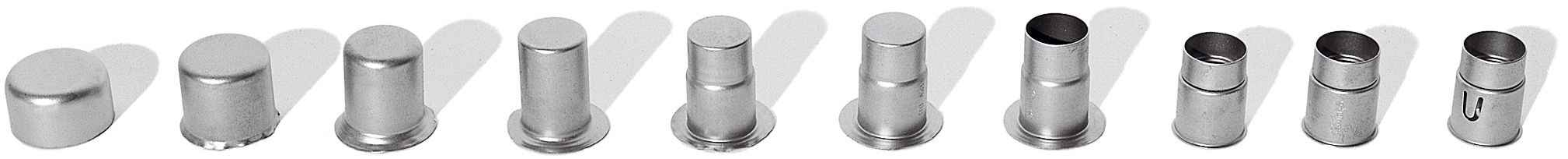

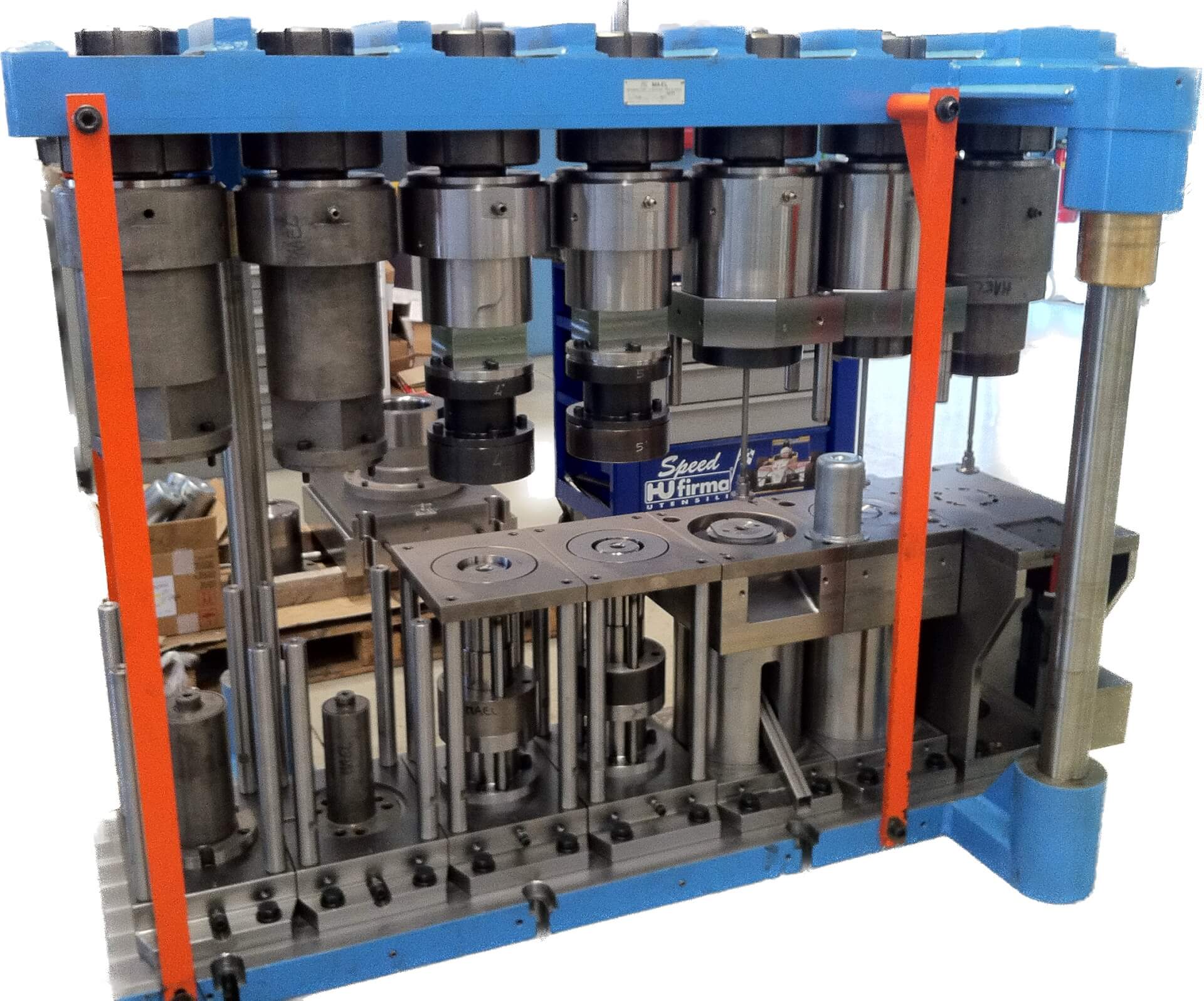

progressive moulds

Maximum flexibility with possibility of use on different machines.

High production speeds and short setup times.

Maximum efficiency in the investment result ratio

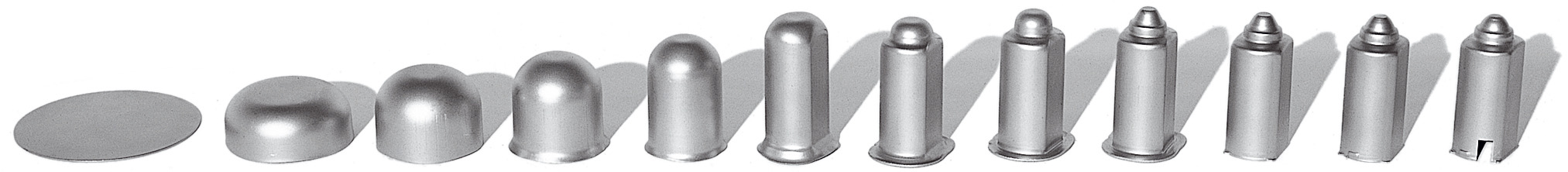

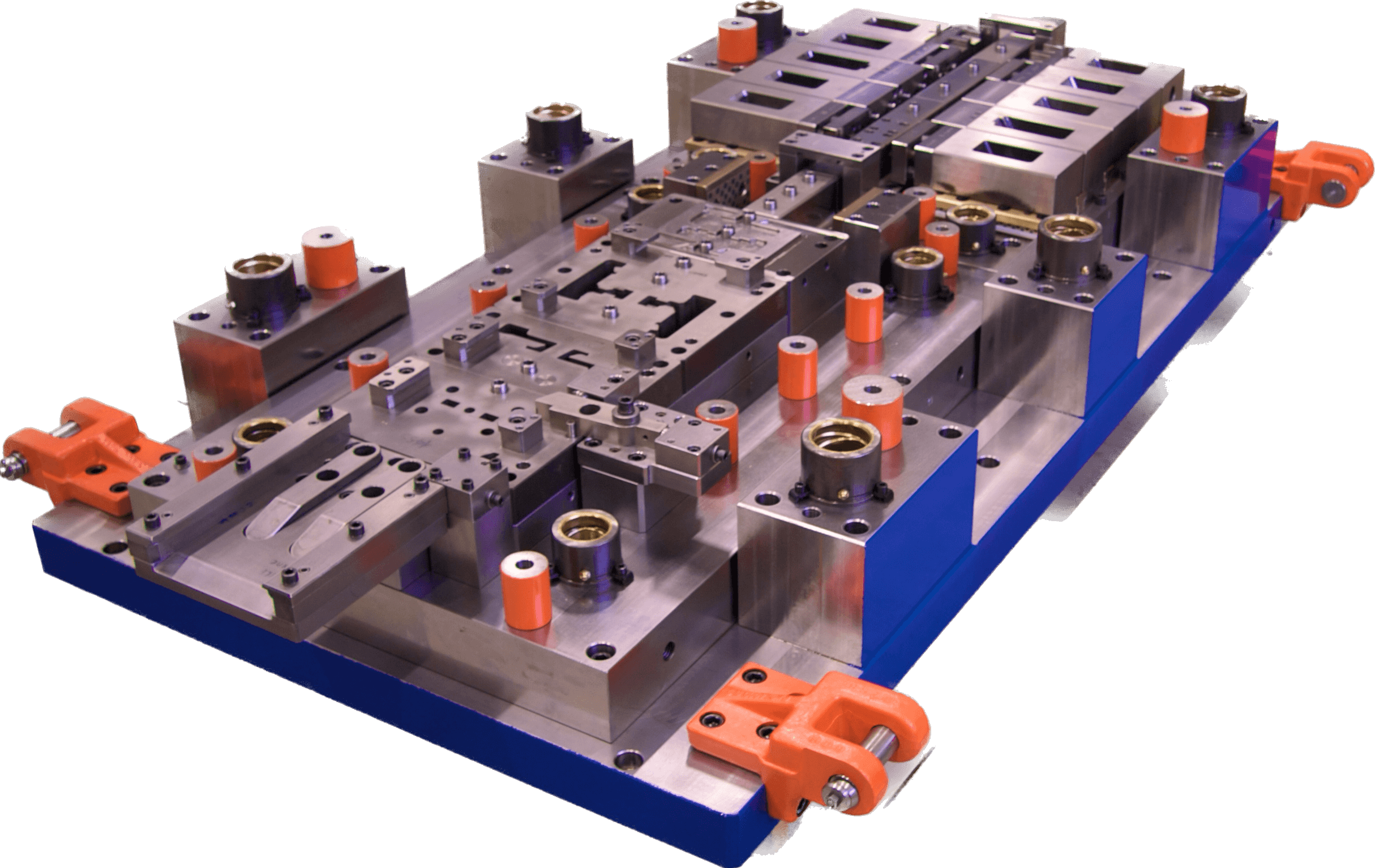

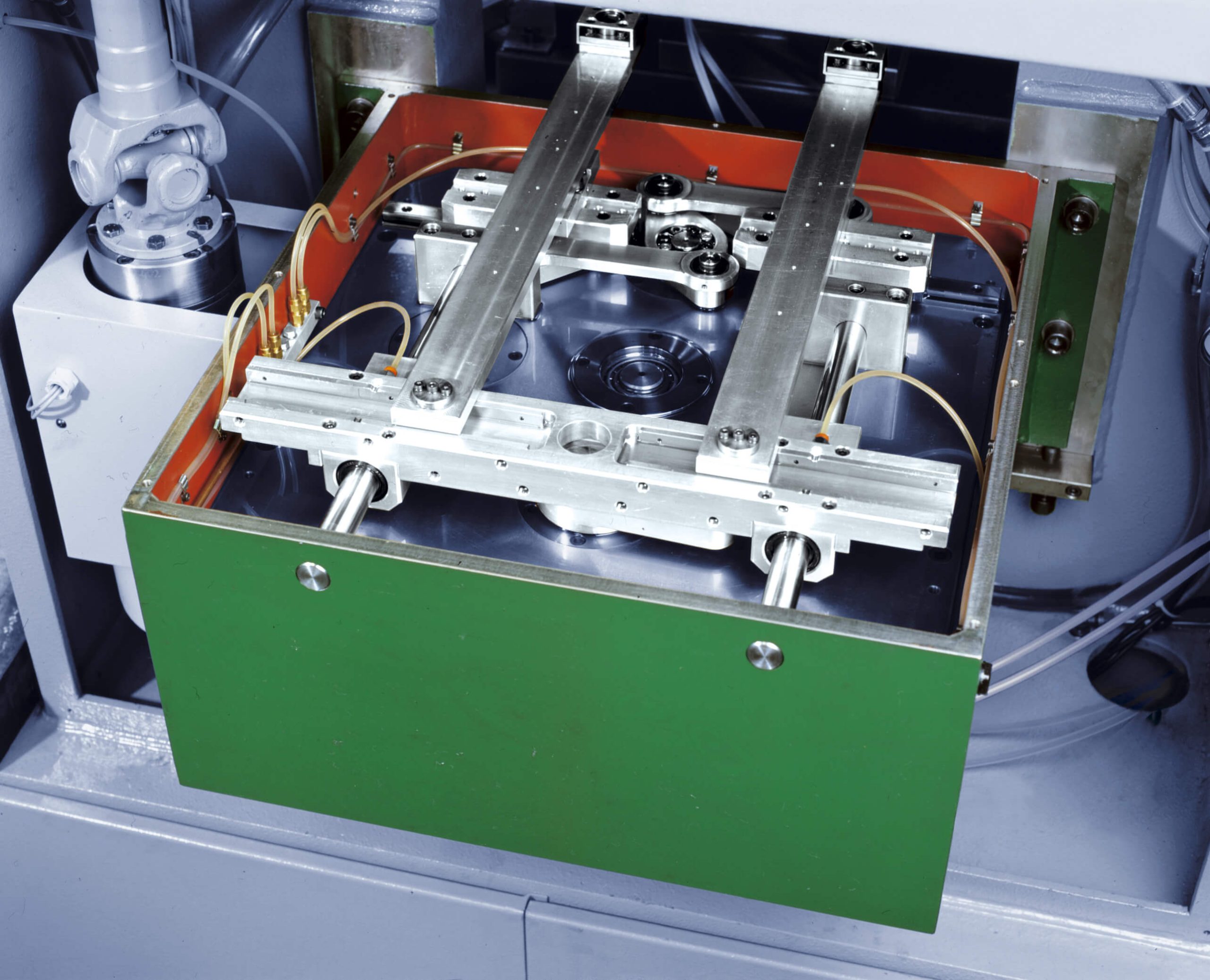

MOULDS FOR FINE BLANKING

Specific for drawing or where it is necessary to have additional operations.

Raw material optimization and maximum waste reduction.

Possibility of off-axis operations with complete embossing of all profiles.

Complex operations within the same production cycle.

Integrated dimensional checks

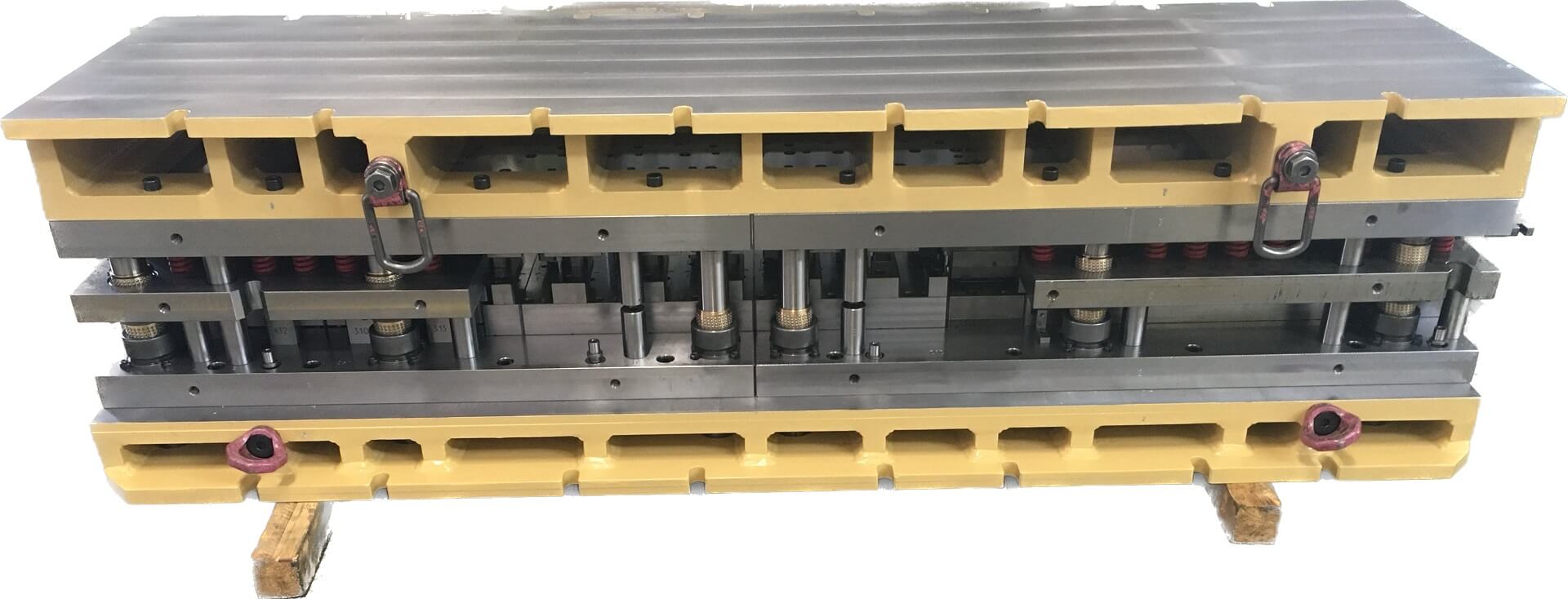

Special production of fine blanking

Specific for drawing or where it is necessary to have additional operations.

Raw material optimization and maximum waste reduction.

Possibility of off-axis operations with complete embossing of all profiles.

Complex operations within the same production cycle.

Integrated dimensional checks

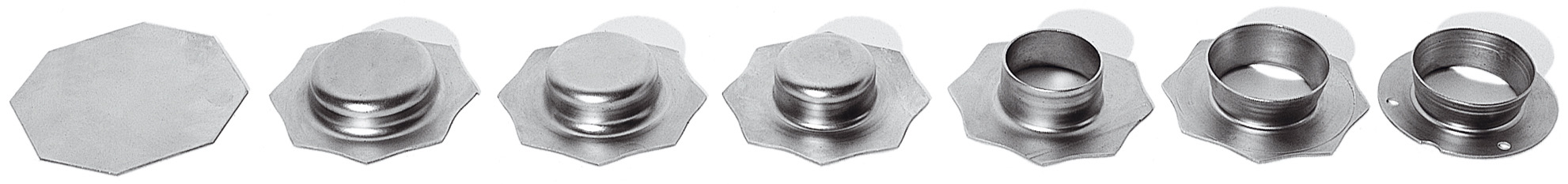

Production of special deep drawn

with a high technological content